SERVICES

Ideas on paper

from napkin

sketches to

dimensional

drawings

STEP 1

.png)

.png)

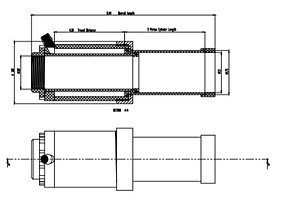

Starting from scratch with an idea &/or some provided measurements alone we can build you a 2D or 3D CAD model. For alot of projects this is all you will need to have your idea manufactured. In this phase its best to aqcuire & provide us with as many measurements or parameters to build around as possible. This will allow us to make a more accurate CAD model to fit your projects needs & can save some engineering/prototyping time down the road depending on the application. We can provide your 2D or 3D model in a ton of different formats, feel free to contact us if you have any questions or for more information about this approach.

Rough CAD

model

in 2D or 3D

file formats

STEP 2

.png)

H.A.R.D. is now offering 3D scanning services to help make more of your ideas possible. From reverse engineering of complex parts to custom components that require OEM quality fitment, we are just a call or email away. Pricing will be quoted on a per job basis so we can provide you with the highest quality services for what you need & make sure you never spend a dime on things you don't. Please contact us with your plans/

ideas so we can help you find the best way to bring your project to life.

original objects

or assemblies from the size of a grapefruit to the size of a truck

STEP 1

By provideing us with an object to start, with or without measurements we can create a 3D Mesh or 3D CAD model in multiple file formats. This will typically be done by using our in house 3D scanners & for some projects this is all you will need to have the starting object re-manufactured or to build from that object a whole new idea/product. Depending on the level of detail/size of your starting object, what computer/software you have at home, & what your plans are for the project; you may need further proccessing of the 3D file still. 3D scanners output cloud point data, we use software to automatically convert that to mesh data but it is still tesselated which means the 3D file provided at this stage will show the triangles that make up the freatures of any curvature on the converted mesh body surface rather than a smooth surface. Objects with flat sides only will not show these triangles. If accurate measurements & locations of specific features on the object are requested we can use the 3D file to acquire measurements or shapes to build around so any critical details from the starting object needed for your project will be included in the files we provide you. Even the most detailed objects we scan can provide us with these types of 3D files & almost any specific features acquired that are requested. When dealing with an object that has less detail & is comprised of more basic shapes &/or flat sides we can eliminate the triangles on the surface of the model provideing a completely smooth surface. Creating this smooth surface on a highly detailed object takes many hrs of manual processing, this is possible if your projects budget allows for it. Overall in many instances this approach can save a ton of reverese engineering time & the measurements acquired from the 3D file data can be within 0.2mm. We can provide your 3D mesh &/or CAD model in multiple different file formats, as well as proccess your files to any stage of this approach so you never pay for anything you dont need. Feel free to contact us with any questions about this approach.

3D CAD model and or 3D mesh

file formats

STEP 2

_edited.jpg)

STEP 3

If your project to do list requires any engineering services or help getting things to the right manufactures we can help you with that too

In both approaches above you can finish step 2 with all the 3D data you need for your project to come to life depending on your experience, what software you have access to, & what manufacturing companies you have access to. If your not sure how to process 3D model files for certain types of manufacturing or how/where to order things for small batch production we can help take you all the way to a prototype part. We can prove details of your concept with simulations, change your files into other formats, create machine drawings, account for tolerancing/bend radius' etc etc...

Many of these engineering skills will be required for certain manufacturing techniques. After completing any engineering that is needed, we will offer to help you get your idea to

manufactures & supply you with any connections we have had good experience with for free.

_edited.jpg)

_edited.jpg)

_edited_edited.jpg)

_edited_edited.jpg)